About us

About Us

Our approach

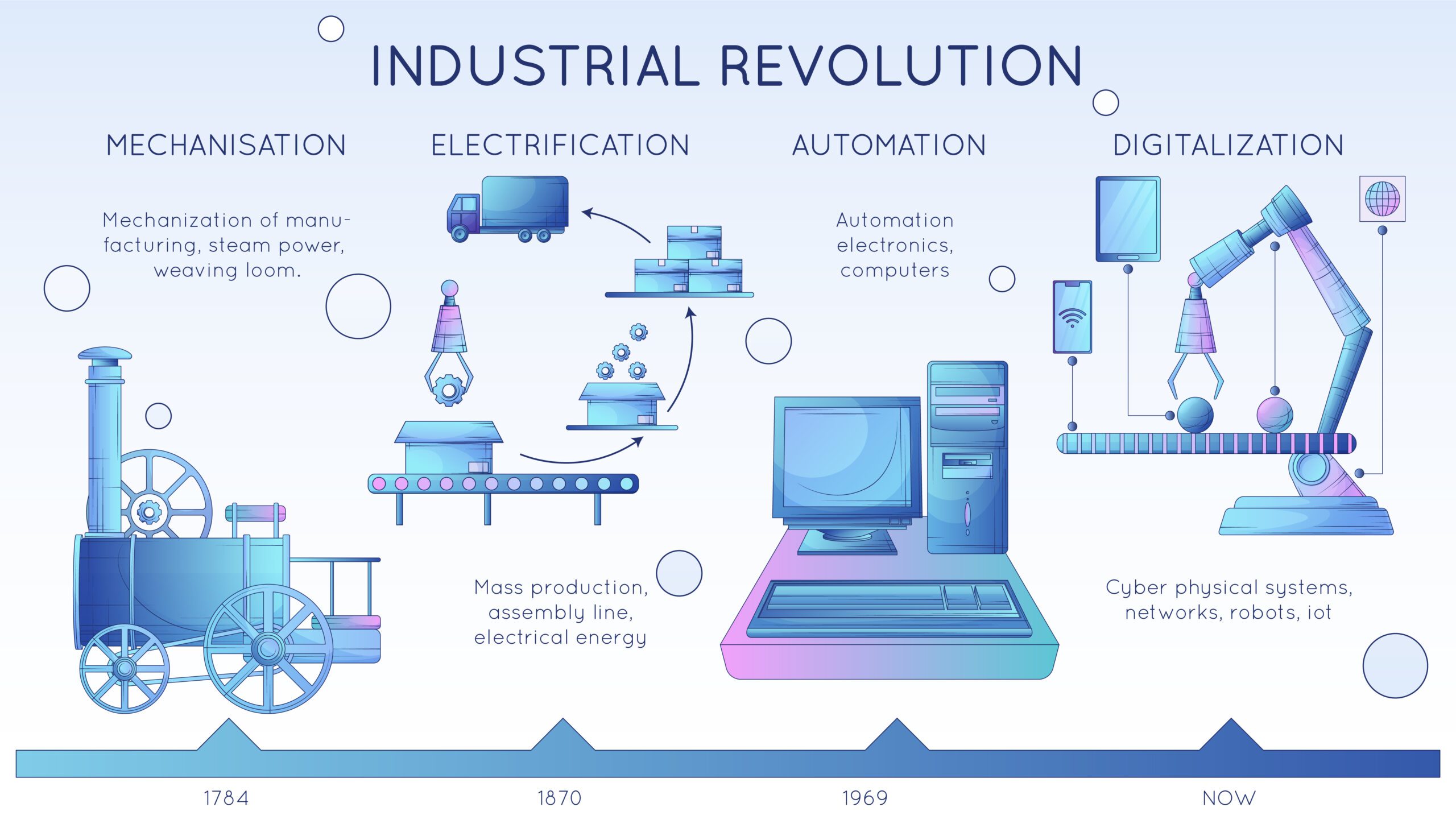

Optegrity is a software platform that aims to help operations teams identify and eliminate bottlenecks throughout the manufacturing lifecycle by utilizing the Theory of Constraints. The concept of a Bill of Operations tied to the Theory of Constraints and Level Loading is central to Optegrity's approach.

Optegrity breaks down manufacturing processes into smaller operations that can be easily assigned to specific manufacturing areas. It provides a set of smart tools to facilitate this process. Visual methods, such as loading charts and value stream what-if analysis tools, are incorporated to assist in moving operations upstream and downstream to eliminate bottlenecks whenever the work sequencing allows. In addition, Optegrity focuses on cross training within the manufacturing environment, making it easy to follow and providing real-time measurement and tracking of cross-training efforts. The platform also incorporates lean concepts such as safety, quality at the source, work standardization, and documentation.

The aim of Optegrity is to provide a comprehensive suite of modules that encompass various lean manufacturing principles and help companies improve their operational efficiency. By emphasizing the analytical aspects of lean thinking, Optegrity distinguishes itself from the interchangeable use of lean and 5S that has become prevalent in many companies today.

Our Story

After quitting from my last corporate job in 2016 as the director of operational excellence and quality assurance, I decided to pursue my dreams of becoming an operations management consultant. I did it and it was, and still is, a great journey and a lot of fun.

As we are helping our clients go through the lean transformation, myself and my partners started seeing some major gaps. We can help these organizations see the value of lean systems and principles and implement them, but after some time, we noticed a decline and lack of attention. But why? The system is working, the results are visible, and there are buy-ins from the stakeholders, so why doesn't it sustain?

Well, we did a lot of research internally, interviewed many operations folks, analyzed good and not-so-good practices, and then we found the gap. Lack of process automation after a lean system is implemented and matures. Keeping track of work instructions, making them up to date after regular improvements and changes, keeping the training matrix, job hazard workbooks, and quality control checklists updated and in sync with the corresponding operations, cumbersome processes to identify the bottlenecks and constraints, not being able to track the people's involvement and cost savings, and this list can go on and on. And that was the inception of Optegrity Solutions.

Mission

Manufacturing is like an orchestra, and the instruments are people, processes, and properties. Keeping these three Ps in sync is the most important and yet challenging part in manufacturing operations management, and this is exactly what we do in Optegrity. We make these connections visible, traceable, and scalable.

We provide the most valuable, affordable, and fun-to-use lean manufacturing software solutions for small and medium manufacturers across the world to develop excellence in their people, processes, and properties. All manufacturers deserve this.

We Promise!

Our suite of applications has been designed to assure people, processes, and properties are in sync. This alignment develops excellence, transparency, agility, integrity, sustainability, and scalability.

Trusted by

Schedule a Personalized Demo

Schedule a demo with our deployment team. Let’s talk about how Optegrity’s modules can integrate with your business and team.